We source our timber from the sustainably managed forests of Scandinavia, where the local climate combination of cold temperatures and the harsh winter season is ideal for producing dense slow-grown trees, which produce tighter grain and therefore stronger premium quality timber. For this reason, all of our structural timbers are the higher C24 strength grade compared to the lower strength C16 grade often found in more moderate climates.

The Scandinavians have long been pioneers in forestry control, sustainability and environmental management. This is why we can offer our customers peace of mind, assured in the knowledge that they are buying some of the best environmental building products in the world. This enables us to offer a complete chain of custody service should your job require it, which tracks the document chain completely back to the source tree.

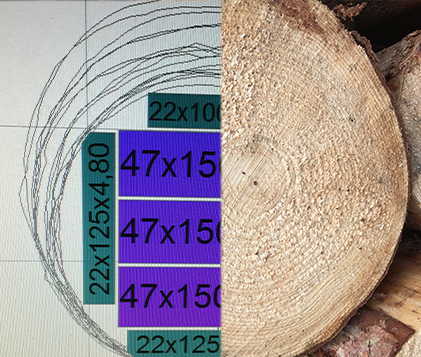

Logs are transported to the sawmill, where they are accurately measured by lasers and a computerised instruction is generated to the automatic saws detailing exactly how each log is to be cut to produce its optimum yield with minimum waste. This includes analysing the taper of the log, debarking the log, and removing serious defects.

The logs are cut into boards/planks ready for drying and further processing.

Our timber is carefully kiln-dried, which is the most effective method of controlling the removal of excess moisture. This process is only completed once we have confirmed the correct moisture content has been reached. This ensures the timber performs at its best and reduces the risk of movement and issues on site. The correct moisture content will also help eradicate any fungal or insect activity present in the log.

The wood is now structurally graded to C24 with the lower grade of C16 being rejected by us, processed and sold for lower grade applications. The strength of C24 timber comes from its density, with the average density of C16 timber being 370kg/m3, compared to the average density of C24 timber at 420kg/m3.

Our C24 timber is then sent for treatment in a controlled environment. We specify a Tanalith E preservative solution applied using a pressurised process, (a much more effective method of treating timber than simply dip treating). This ensures the wood structure is correctly penetrated, resulting in the best resistance to fungal and insect attack.

We even specify an upgraded UC4 treatment level on our Deck joists, meaning that they are still resistant to decay if buried in the ground.

The timber is now approved to be part of our Joistmate Extra range, additionally wrapped with protective sheeting and shipped in bulk straight to our branches, stored undercover and ready for you to order online, collect or arrange delivery to site.